The “Delicate Method”:

flavour and texture

Benedetto Cavalieri’s

pasta production.

THE RIGOROUS SELECTION

OF ITALIAN DURUM WHEATS

THE “DELICATE” METHOD

This processing method ensure pasta that typical aromatic taste and a completely natural chewy texture so appreciated by chefs and sensible appetites. It consists on a long kneading, a slow pressing, bronze-die drawing and drying at a low temperature. All this allows to preserve its typical grain flavour, to ensure the absolutely natural consistency and that great permeability to the condiments. Finally, the “Delicate Method”, guarantees the complete preservation of the precious nutritional values of the best durum wheat.

THE KEENNESS FOR PASTA,

THE CURE AND THE CONSTANT RESEARCH FOR THE BEST QUALITY

That the Cavalieri family hands out from generation to generation.

Pasta production

with the “Delicate Method”

1. KNEADING STAGE

Raw material is the durum wheat semolina. Every shape of pasta needs a convenient blend that, from special silos, automatically passes on to a measuring device that releases the correct amount of water and semolina. Cold kneading (no more than 35°C/95°F), regulated by skilled hands, prevents the “thermic denaturation” of gluten, the highly valuable nutrient contained in wheat.

2. KNEADING, PRESSING,

AND EXTRUSION

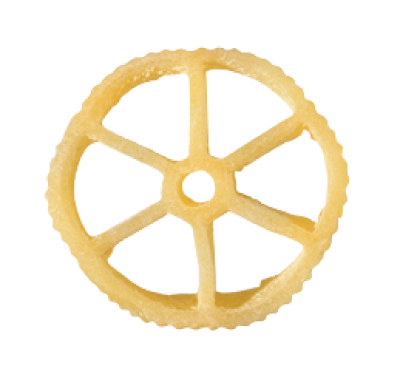

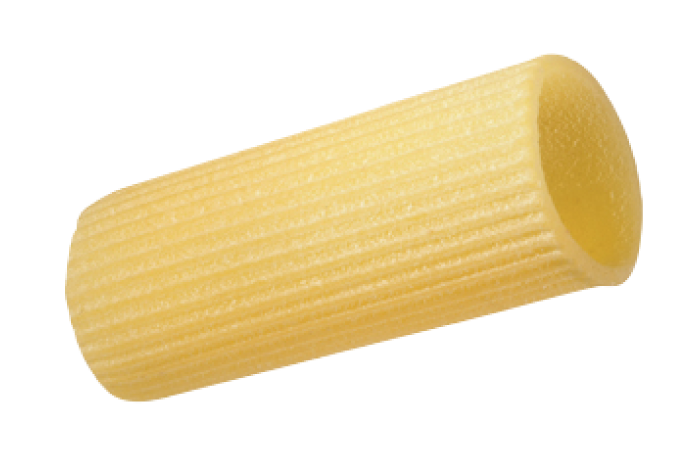

From the kneading machine, automatically, the dough is pressed through a mould with “gentle” pressing which prevents the “mechanical destruction” of gluten and carbohydrates. For every shape of pasta there is a mould with lots of holes. We still use moulds, made by special bronze alloy, that have many “pasta rooms” funnel milled for every hole. The mixture passes “gently” through these holes to take its final form: spaghetti, penne etc. At this point pasta must be appropriately dried to be preserved.

3. DRYING STAGE

AT A LOW TEMPERATURE

To prevent the “denaturation” of proteins and carbohydrates:

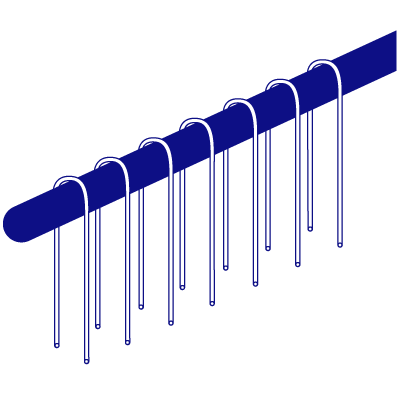

• Long pasta (e.g., spaghetti), soon after drawing, is automatically placed on rods and enters the drying room, where it undergoes alternating cycles of warm ventilation and “rest.”

• Short pasta (e.g., penne) by special motor knives is cut into segments while coming out of the mould and is placed on conveyor belts that push it into the drying room where it undergoes the similar drying treatment described above for long pasta.

4. STABILIZATION PHASE

Once the drying process has taken place, pasta needs to rest in an air-conditioned room before being weighed and packaged. Controls are carried out at every stage of the working process and of the packaging stage by our skilled and reliable Staff.

Low temperature refers to air drying at no more than 54°C/129,2 °F, corresponding to a maximum pasta temperature of 46°C/114,8 °F. Drying times range from a minimum of 20 hours to a maximum of 40 hours, depending on the shape and thickness of the pasta.

Unlike industrial “high-temperature” systems (up to 120°C/248°F with drying times as short as 3 hours), our “Delicate Method” achieves excellence in nutritional quality by preserving the valuable nutrients of durum wheat (plant-based proteins and carbohydrates, the basis of the Mediterranean Diet) while also achieving outstanding organoleptic quality, enhancing the unique taste and natural consistency so highly valued to this day.