Benedetto Cavalieri Pasta is widely known for:

- the rigorous selection of italian durum wheats that grow in purposely chosen fields especially on the hills of Apulia and Basilicata (South of Italy); the durum wheat is cultivated without the usual massive use of chemical fertilizers that increases the quantities at the expense of quality;

- the processing method called ‘Delicate’: the long kneading, the slow pressing, drawing and drying at a low temperature permit to preserve the nutritional values of the durum wheat, its taste and typical flavour and to secure a completely natural consistency;

- the keenness for pasta, the cure and the constant research for the best quality that the Cavalieri Family hands out from generation to generation.

Description of the pasta making process through the ‘Delicate Method’:

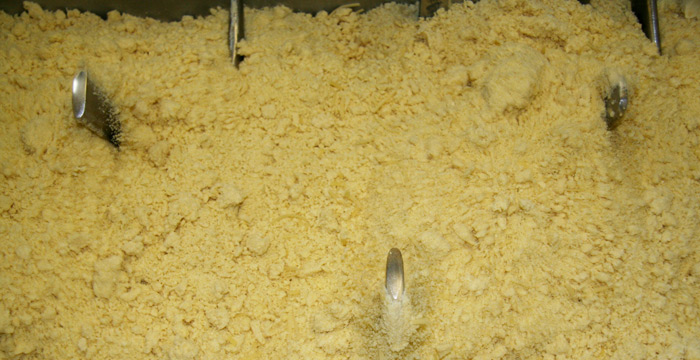

Mixing stage: each shape needs a convenient blend of durum wheat semolinas. From special silos, automatically they pass on to a measuring device that releases the correct amount of water and semolina. Cold kneading ( not above 35°), controlled by experienced hands, prevents ‘thermic denaturation’ of gluten, the precious nutritional substance contained in the wheat.

Kneading, pressing and drawing stage: from the kneading machine, automatically, the dough is pressed through a mould with gentle pressing which prevents the ‘mechanical destruction’ of gluten and carbohydrates . For each shape of pasta there is a mould with lots of holes. We still use moulds made by a special bronze alloy, that have many funnel-shaped ‘pasta rooms’, milled for each hole. The dough passes gently through these holes to take its final form: spaghetti, penne…

At this point pasta must be appropriately dried to be preserved.

Drying stage at a low temperature to preserve the nutritional values of gluten:

Long cuts (spaghetti, etc.) soon after drawing are hung on reeds and subjected to a drying process that takes place in drying rooms, on four levels with an alternating period of moderately warm ventilation and a ‘rest’ period.

Short cuts (penne, etc.) : by special motor knives they are cut into segments while coming out of the mould and are placed on conveyor belts that push them into the drying room where they undergo the similar drying treatment described above for spaghetti pasta.

When we speak of low temperature we mean that the temperature of the air in the drying room is no more than 54°C and that pasta reaches only 40°C. Due to a difference in shape and thickness each cut of our pasta has a different drying period which can vary from 36 to a total of 40 hours.

Unlike the industrial drying systems at ‘high temperature’ (they reach 120°C with a drying time up to 3 hours), our Delicate Method permits to obtain the excellence of the nutritional quality, as it preserves the precious biological and nutritive values of durum wheat (carbohydrates, vegetable proteins: basis of the Mediterranean Diet) and, at the same time, the excellence of the organoleptic quality as it brings out that unique taste and that completely natural consistency which is so appreciated still today.

‘Stabilization’ stage: once the drying process has taken place, the pasta needs to rest (for approximately 24 hours) in an advisably air-conditioned room before being weighed and packaged.

Controls are carried out at every stage of the working process and of the packaging by our skilled and reliable Staff.